These VA Tech scientists are building a better fog harp

Combining vertical “strings” with periodic horizontal wires stops clogging and clumping, boosts efficiency.

Credit:

Alex Parrish for Virginia Tech

A fog harp prototype collects water vapor. Credit: Virginia Tech

Arid coastal regions that are also prone to fog are prime locations for fog-harvesting devices as a water source, especially during prolonged droughts. But the standard technology is prone to clogging. Scientists at Virginia Tech have created an improved version of their earlier “fog harp” alternative design to address that issue, according to a new paper published in the Journal of Materials Chemistry A.

Fog harvesting (or dew catching) is an ancient practice dating as far back as the Incas, who placed buckets under trees to collect condensation. It’s also practiced by certain insects, notably Namib desert beetles, which survive on the water that condenses onto their wings. The wings have alternating hydrophilic and hydrophobic regions to enhance the condensation. Today’s fog harvesters are usually mesh nets mounted onto frames with a trough or basin underneath. Like the beetle’s wings, the mesh filaments are chemically coated to be either hydrophobic or hydrophilic.

The efficiency of these water harvesters depends on decreasing the size of the filaments and the mesh holes. “If the holes were too big, the microscopic droplets would pass through it, and it wouldn’t harvest much water,” co-author James Kaindu, a student in researcher Jonathan Boreyko’s lab at Virginia Tech, told Ars. The trade-off is that smaller filaments and holes are more prone to clogging. “If it was too small, the droplets would coalesce and create a water film on it,” said Kaindu. “It would impede the flow and act as a barrier that would dramatically affect its capture efficiency.”

That’s why Boreyko’s group came up with the fog harp in 2018. As the name implies, the fog harp consists of a frame holding vertical wires with no criss-crossing horizontal ones. It was inspired by California redwoods, which derive as much as 35 percent of their annual water intake from fog dripping from the parallel arrays of the trees’ needle-like leaves.

Jonathan Boreyko (l) and Brook Kennedy (r) in 2018 with the original fog harp.

Credit:

Peter Means for Virginia Tech

The design performed very well in the laboratory during scale model testing, collecting between two to seven times the amount of water as mesh nets. But then they tested their design in Monterey Bay. That real-world deployment required larger versions on the order of 1 meter by 1 meter (or 3×3 feet). At that larger scale, surface tension becomes an issue, and the vertical strands start to clump together, “like your hair when it gets clumped up with water,” said Kaindu. And once again, there are reduced harvesting efficiencies.

Best of both worlds

So the team decided upon a happy medium, combining elements of the traditional mesh with the fog harp to create a hybrid version: essentially a series of small-scale model fog harps stacked on top of each other, separated by the occasional cross-support wire. Boreyko likens the structure to a guitar neck with clearly demarcated frets. This eliminated the clumping problem to get the desired water harvesting efficiency.

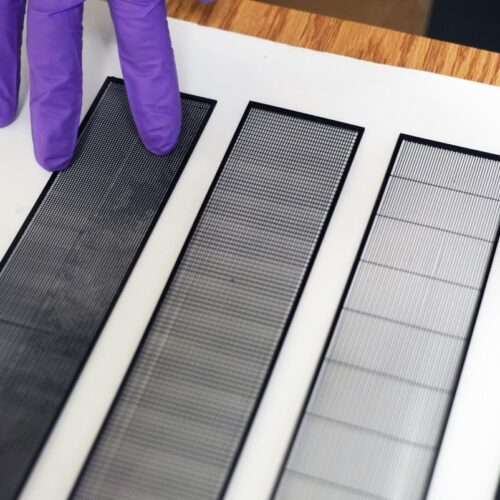

Per Kaindu, the team tested variations of the concept in the lab, from standard mesh nets on one end, with their many interconnects, up to the original fog harp on the other extreme, with none. In between were versions with a hundred interconnects, 10 interconnects, five interconnects, and three interconnects. All were suspended in the air and blasted with fog from ultrasonic humidifiers.

Next they measured the mass of collected water after a specified time period to arrive at the overall efficiency—the fraction of all the fog water in the air relative to how much was captured—for each variation. The improved hybrid fog harp increased fog harvesting efficiency by a factor of between two and eight compared to pure mesh fog harvesters and the original fog harp, depending on other variables. The designs with three and five interconnects proved to be the sweet spot for the highest efficiency.

Unlike standard fog harvesting technologies, “We’re trying to use clever geometric designs in place of chemistry,” Boreyko told Ars. “When I first came into this field, virtually everyone was using nets, but they were just trying to make more and more clever chemical coatings to put on the nets to try to reduce the clogging. We found that simply going from a net to a harp, with no chemicals or coatings whatsoever—just the change in geometry solved the clogging problem much better.”

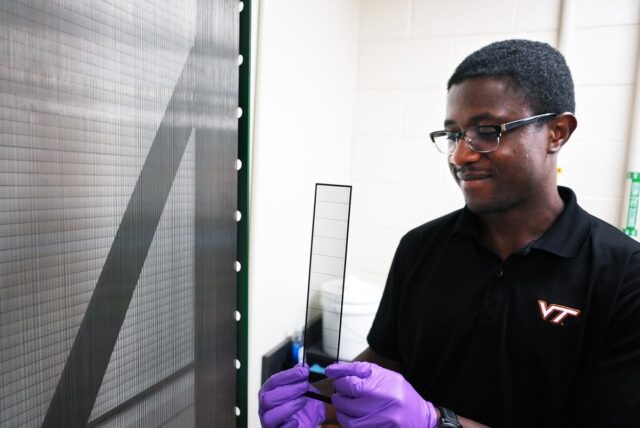

Jimmy Kaindu inspects a new collecting prototype beside the original fog harp.

Credit:

Alex Parrish for Virginia Tech

For their scale prototypes in the lab, Boreyko’s team 3D printed their harp “strings” out of a weakly hydrophobic plastic. “But in general, the harp works fantastic with uncoated stainless steel wires and definitely doesn’t require any kind of fancy coating,” said Boreyko. And the hybrid harp can be scaled up with relative ease, just like classic nets. It just means stringing together a bunch of harps of smaller heights, meter by meter, to get the desired size. “There is no limit to how big this thing could be,” he said.

Scaling up the model is the next obvious step, along with testing larger prototypes outdoors. Boreyko would also like to test an electric version of the hybrid fog harp. “If you apply a voltage, it turns out you can catch even more water,” he said. “Because our hybrid’s non-clogging, you can have the best of both worlds: using an electric field to boost the harvesting amount in real-life systems and at the same time preventing clogging.”

While the hybrid fog harp is well-suited for harvesting water in any coastal region that receives a lot of fog, Boreyko also envisions other, less obvious potential applications for high-efficiency fog harvesters, such as roadways, highways, or airport landing strips that are prone to fog that can pose safety hazards. “There’s even industrial chemical supply manufacturers creating things like pressurized nitrogen gas,” he said. “The process cools the surrounding air into an ice fog that can drift across the street and wreak havoc on city blocks.”

Journal of Materials Chemistry A, 2025. DOI: 10.1039/d5ta02686e (About DOIs).

Jennifer is a senior writer at Ars Technica with a particular focus on where science meets culture, covering everything from physics and related interdisciplinary topics to her favorite films and TV series. Jennifer lives in Baltimore with her spouse, physicist Sean M. Carroll, and their two cats, Ariel and Caliban.